The 5-Step Development Process of a Custom Capacitive Touchscreen by Yunlea

The 5-Step Development Process of a Custom Capacitive Touchscreen by Yunlea

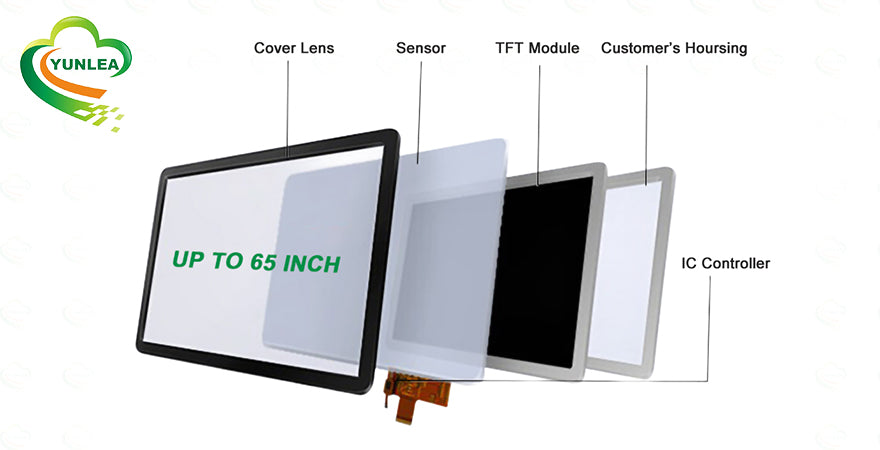

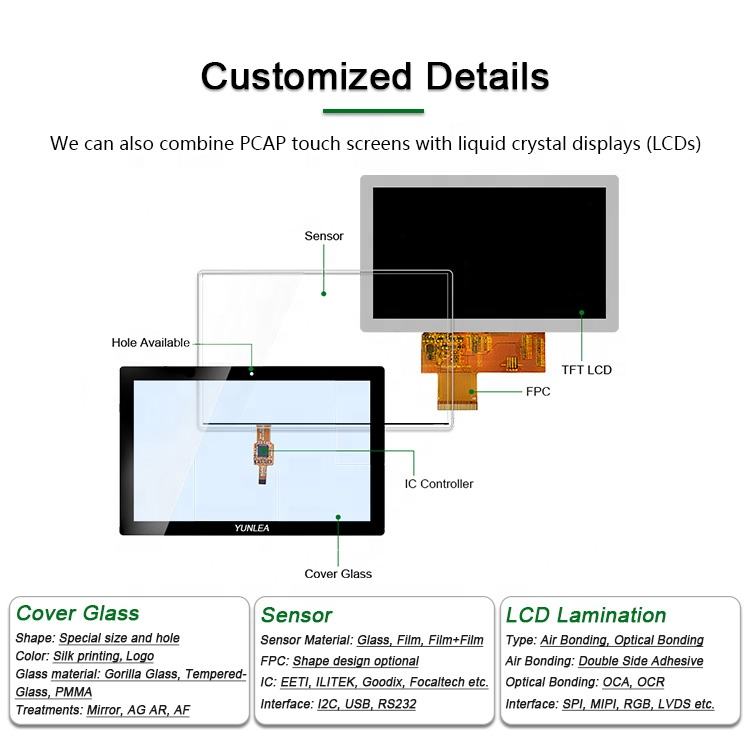

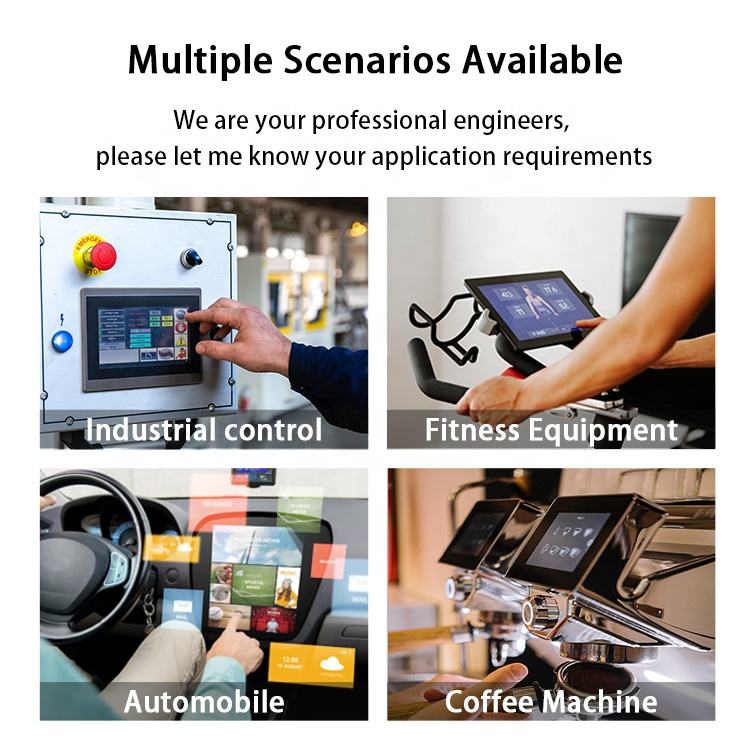

The development of a capacitive touchscreen involves a systematic approach that begins with conceptualization and ends with mass production. Each stage of development is critical, requiring detailed attention to ensure that the final product meets the technical and practical requirements of the user. This guide outlines Yunlea's five-step development process for capacitive touchscreens.

1. Definition

Understanding the Need: The development process begins with a comprehensive questionnaire to understand the client's needs.

Questions include:

What problem are you trying to solve with this product?

How does this touchscreen solution address that problem?

What are the specifics of the product, application, and timeline?

Why are particular requirements (size, shape, etc.) necessary for this project?

This phase helps align the project objectives with the client’s needs, setting a clear foundation for the development.

2. Concept

Prototype Development: Based on the initial specifications gathered from the questionnaire, prototype tooling orders are placed. These early samples are critical for justifying the proof of concept, allowing stakeholders to see and feel the proposed solution and make necessary adjustments early in the process.

3. Design

Engineering and Final Quotations: Once the proof of concept is approved, a formal quote is provided, and production orders for the required materials are placed. This stage involves detailed design and engineering efforts to finalize every aspect of the touchscreen, from its electrical design to its physical dimensions and interface.

4. Validation

Client Approval: In this crucial step, you, as the client, validate the efficacy of the custom-designed touchscreen. This validation process ensures that the product meets all specified requirements and performs as expected in real-world scenarios. Adjustments and refinements are made based on feedback to prepare the product for mass production.

5. Production

Manufacturing and Launch: Production begins with a short run of the parts to finalize all manufacturing processes and setups. This initial production is scaled up to full mass production as all quality checks are completed. The final step involves preparing and executing the launch plan to deliver the quantities necessary for market introduction.

By following this five-step process, Yunlea ensures that each custom capacitive touchscreen project is handled with precision and care, meeting all client specifications and industry standards.

We are a professional touch screen manufacturer. Welcome to customize your capacitive touch screen. Contact us directly!

The development of a capacitive touchscreen involves a systematic approach that begins with conceptualization and ends with mass production. Each stage of development is critical, requiring detailed attention to ensure that the final product meets the technical and practical requirements of the user. This guide outlines Yunlea's five-step development process for capacitive touchscreens.

1. Definition

Understanding the Need: The development process begins with a comprehensive questionnaire to understand the client's needs.

Questions include:

What problem are you trying to solve with this product?

How does this touchscreen solution address that problem?

What are the specifics of the product, application, and timeline?

Why are particular requirements (size, shape, etc.) necessary for this project?

This phase helps align the project objectives with the client’s needs, setting a clear foundation for the development.

2. Concept

Prototype Development: Based on the initial specifications gathered from the questionnaire, prototype tooling orders are placed. These early samples are critical for justifying the proof of concept, allowing stakeholders to see and feel the proposed solution and make necessary adjustments early in the process.

3. Design

Engineering and Final Quotations: Once the proof of concept is approved, a formal quote is provided, and production orders for the required materials are placed. This stage involves detailed design and engineering efforts to finalize every aspect of the touchscreen, from its electrical design to its physical dimensions and interface.

4. Validation

Client Approval: In this crucial step, you, as the client, validate the efficacy of the custom-designed touchscreen. This validation process ensures that the product meets all specified requirements and performs as expected in real-world scenarios. Adjustments and refinements are made based on feedback to prepare the product for mass production.

5. Production

Manufacturing and Launch: Production begins with a short run of the parts to finalize all manufacturing processes and setups. This initial production is scaled up to full mass production as all quality checks are completed. The final step involves preparing and executing the launch plan to deliver the quantities necessary for market introduction.

By following this five-step process, Yunlea ensures that each custom capacitive touchscreen project is handled with precision and care, meeting all client specifications and industry standards.

We are a professional touch screen manufacturer. Welcome to customize your capacitive touch screen. Contact us directly!