From Liquid Crystals to Visual Brilliance: A Professional Guide to LCD Technology by a 17-Year Industry Expert

From Liquid Crystals to Visual Brilliance: A Deep Dive into LCD Technology

In the world of modern display technology, LCD (Liquid Crystal Display) remains one of the most mature, reliable, and widely adopted display solutions. From smartphones and tablets to industrial HMI panels, medical devices, automotive infotainment systems, and outdoor commercial displays, LCD technology continues to serve as the visual backbone of countless applications worldwide.

Despite the rapid emergence of newer display technologies, LCD has maintained its dominant position thanks to its stable performance, excellent cost-to-performance ratio, scalable manufacturing, and proven long-term reliability. For industries where consistency, durability, and supply chain stability are critical, LCD remains a trusted choice.

With over 17 years of deep involvement in the display and touchscreen industry, the Yunlea team has witnessed firsthand the evolution of LCD technology—from early monochrome panels to today’s high-brightness, wide-viewing-angle, industrial-grade TFT LCDs. In this article, we share a professional, engineering-oriented breakdown of how LCD works, its internal structure, key advantages, and why it continues to play a vital role in modern display systems.

Understanding Liquid Crystals and How LCD Works

At the heart of LCD technology are liquid crystals, a unique state of matter that exhibits characteristics of both liquids and solid crystals. Unlike OLED or LED pixels, liquid crystals do not emit light on their own. Instead, they function as precise light modulators, controlling how light passes through each pixel.

In a standard LCD panel, liquid crystals are sandwiched between two transparent electrodes, typically made of ITO (Indium Tin Oxide), and sealed within glass substrates. Each substrate is coated with alignment layers that define the default orientation of the liquid crystal molecules.

When an electric voltage is applied to the electrodes, the liquid crystals rotate or realign in response to the electric field. This change in molecular orientation alters the polarization state of incoming light. By controlling this process at the pixel level, the LCD can selectively allow light to pass through or block it—forming images, text, and graphics with high precision.

This electro-optical control mechanism is the foundation of LCD’s excellent image stability, uniformity, and long operational lifespan, making it especially suitable for professional and industrial environments.

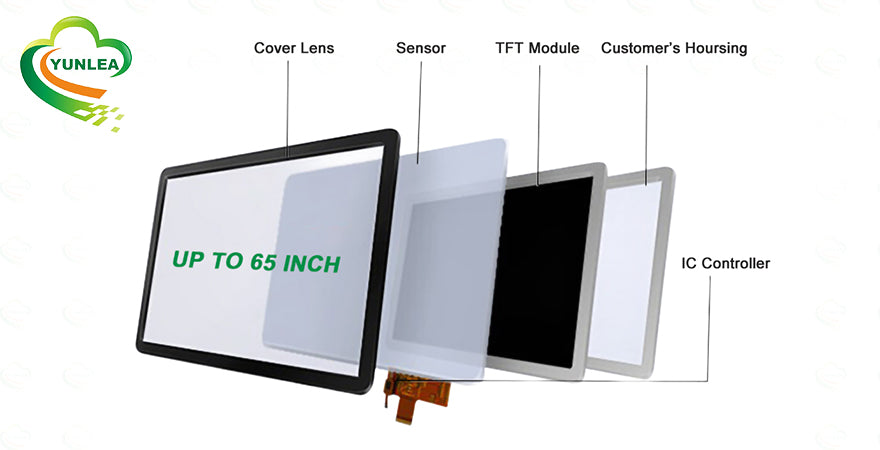

Key Layers of an LCD Display

A modern LCD display is a highly engineered optical system composed of multiple functional layers, each playing a critical role in image formation:

Backlight Unit (BLU)

The backlight provides a consistent white light source for the entire panel. Most modern LCDs use LED backlighting, offering higher brightness, better energy efficiency, and longer lifespan. Industrial LCDs often adopt high-brightness LED backlights to ensure visibility in outdoor or high-ambient-light environments.

Polarizing Filters

Polarizers are positioned before and after the liquid crystal layer. They control the direction of light waves entering and exiting the panel, enabling the liquid crystals to modulate light effectively.

Liquid Crystal Layer

This is the core functional layer where voltage-controlled liquid crystal alignment determines light transmission. Precise control at each pixel allows for accurate grayscale and image rendering.

Color Filter Layer

The color filter divides each pixel into red, green, and blue (RGB) sub-pixels, which combine to produce full-color images. High-quality color filters are essential for color accuracy and consistency, particularly in medical and professional display applications.

Through precise coordination of these layers, LCD technology delivers sharp text, detailed graphics, consistent brightness, and stable color performance.

Advantages of LCD Technology

Over decades of real-world application, LCD technology has proven its strengths across multiple industries:

-

High Resolution & Image Stability

LCD panels provide consistent image quality without burn-in, even during long-term static display. -

Low Power Consumption

Especially when paired with efficient LED backlights, LCDs offer excellent energy efficiency. -

Long Service Life & Reliability

Industrial-grade LCDs are designed for continuous operation, temperature stability, and vibration resistance. -

Wide Application Compatibility

LCD technology scales easily across different sizes, resolutions, and environments—from consumer electronics to mission-critical industrial systems.

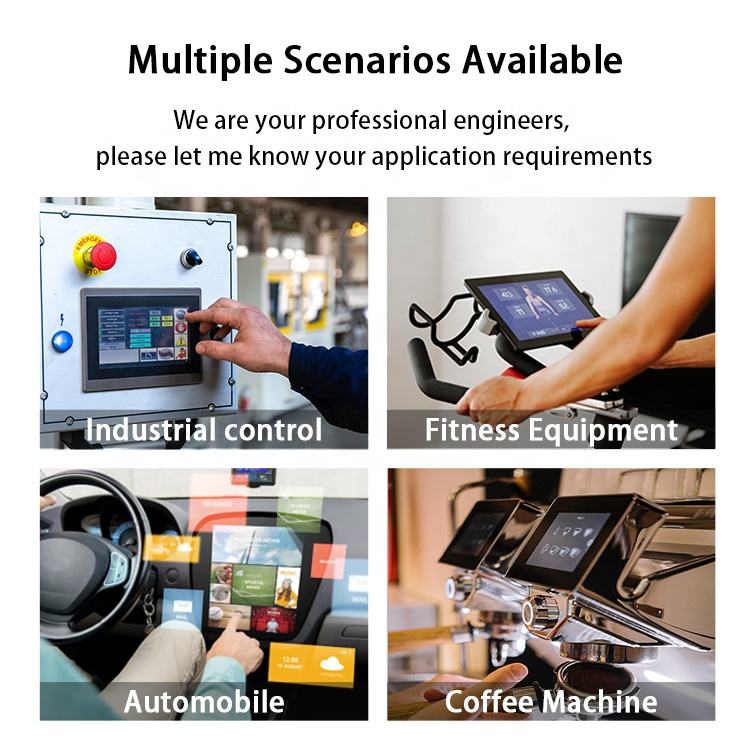

These characteristics make LCD displays particularly well-suited for industrial touchscreens, medical equipment, automotive displays, kiosks, and commercial control systems, where reliability and longevity are essential.

Evolution of LCD Displays

LCD technology has continuously evolved to meet higher performance requirements and application demands. Among the most widely adopted variants are:

TFT-LCD (Thin-Film Transistor LCD)

TFT technology integrates a dedicated transistor at each pixel, significantly improving response time, brightness control, contrast ratio, and image sharpness. Today, TFT LCD has become the industry standard for most color LCD applications.

IPS-LCD (In-Plane Switching LCD)

IPS technology enhances viewing angles and color accuracy by keeping liquid crystal molecules parallel to the panel surface. This makes IPS LCDs ideal for applications requiring wide viewing angles, consistent color reproduction, and professional-grade visual performance.

These advancements have enabled LCD displays to expand far beyond basic visualization, supporting high-end, precision-driven applications across multiple industries.

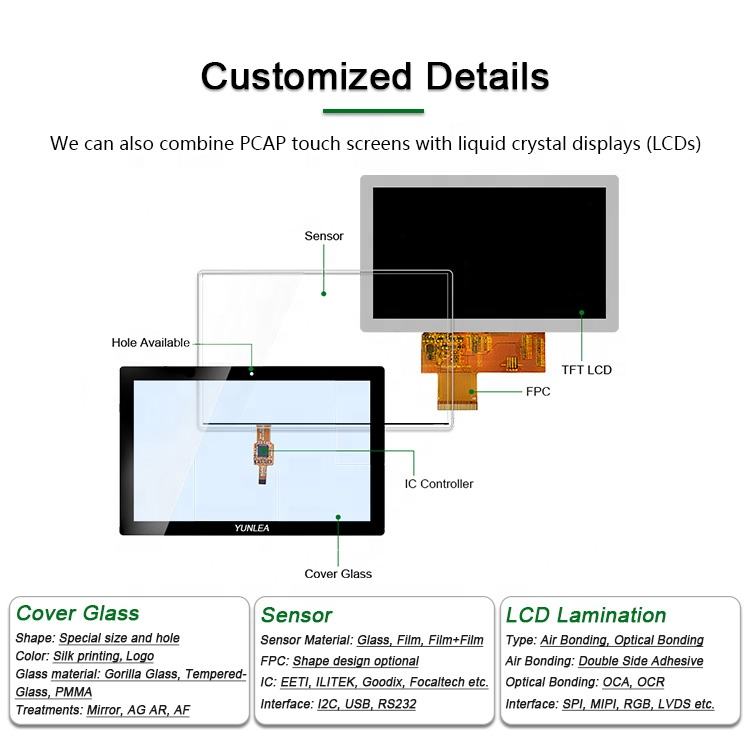

Custom LCD & Touchscreen Solutions from Yunlea

At Yunlea, we focus on delivering custom LCD and touchscreen solutions tailored to real-world application needs. Leveraging 17 years of industry expertise, we integrate:

-

High-quality TFT LCD panels

-

Capacitive touchscreens

-

Advanced optical bonding technologies

-

Mechanical and electrical customization

From display selection and touch integration to optical bonding and final assembly, we support your project throughout the entire development lifecycle—ensuring performance, reliability, and long-term value.

📩 Looking for a reliable LCD or touchscreen solution?

Contact Yunlea today to discuss your requirements with our experienced engineering team.