Advantages and Disadvantages of the Lamination Method in TFT LCD with Capacitive Touch Screen

Introduction

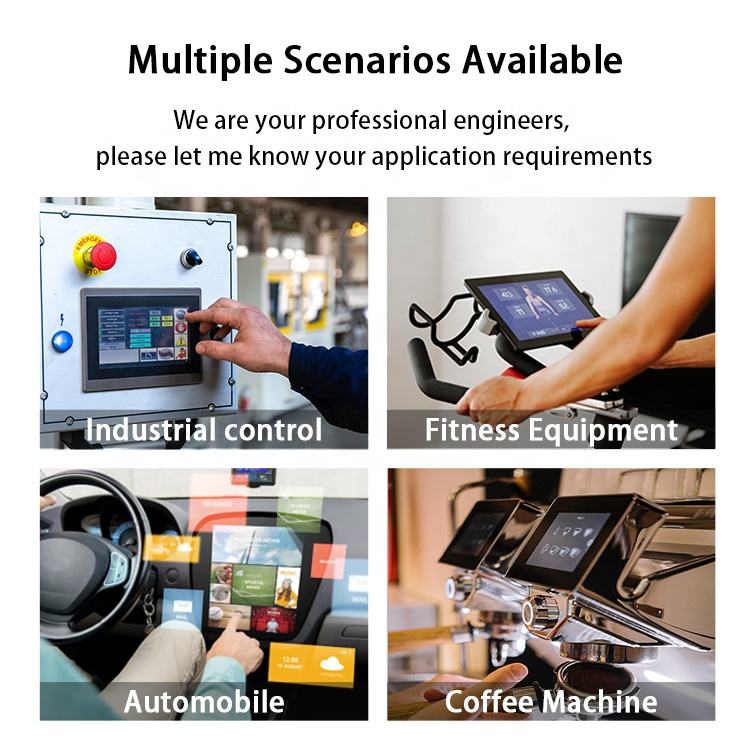

Thin-Film Transistor Liquid Crystal Displays (TFT LCDs) with capacitive touch screens are widely used in smartphones, tablets, monitors, and other interactive devices.

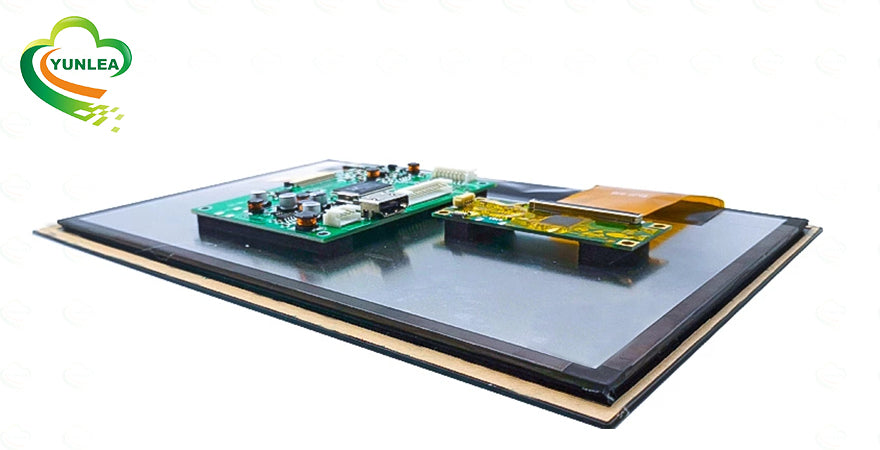

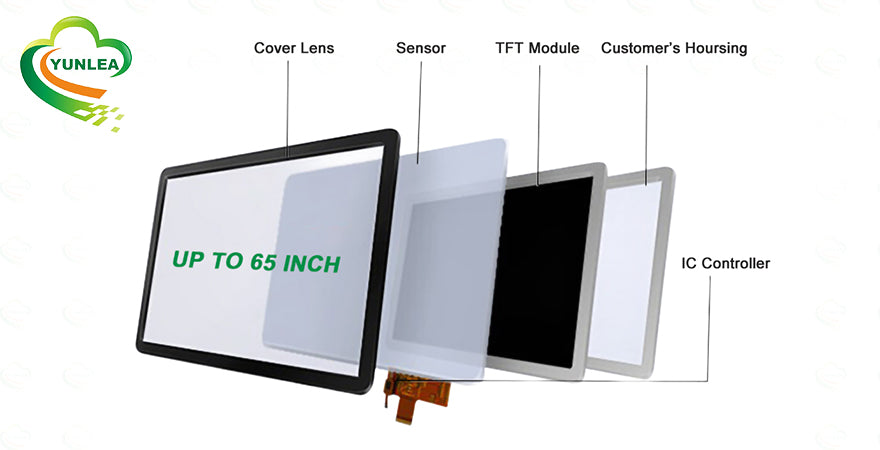

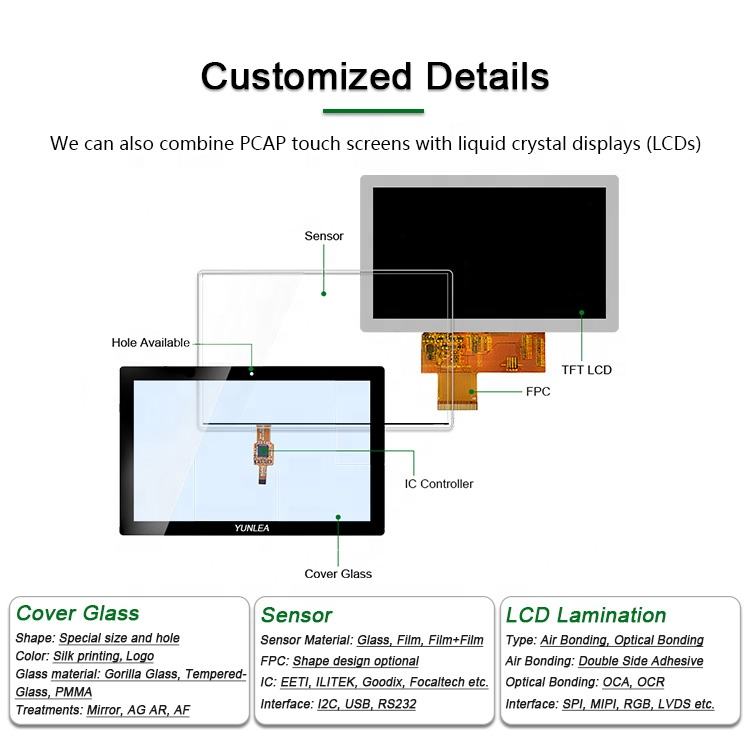

A key manufacturing step for these displays is lamination, which bonds multiple layers—such as the cover glass, touch sensor, and LCD panel—together using Optically Clear Adhesive (OCA) or Optically Clear Resin (OCR).

The lamination method plays a critical role in determining optical quality, durability, and touch performance, but it also brings certain challenges. This article explores the main advantages and disadvantages of lamination in TFT LCD manufacturing.

Advantages of the Lamination Method

1. Improved Optical Clarity

-

Eliminates air gaps, reducing light refraction and reflection.

-

Results in higher brightness, contrast, and better sunlight readability.

-

Enhances viewing angles with minimal glare.

2. Enhanced Durability and Impact Resistance

-

Adhesive layers absorb shock, reducing damage from drops.

-

Protects against dust and moisture for longer lifespan.

3. Better Touch Sensitivity and Accuracy

-

Consistent touch response across the entire screen.

-

Reduces parallax error for more precise interactions.

4. Slimmer and Lighter Design

-

Eliminates bulky air gaps for a thinner profile.

-

Supports sleek and modern device aesthetics.

5. Improved Manufacturing Yield

-

Advanced vacuum lamination reduces defects like bubbles and delamination.

-

Automation increases consistency and lowers long-term costs.

Disadvantages of the Lamination Method

1. Higher Manufacturing Complexity and Cost

-

Requires cleanroom environments and precision vacuum equipment.

-

OCA/OCR adhesives cost more than traditional assembly materials.

2. Risk of Delamination and Bubble Formation

-

Poor lamination can cause air bubbles and reduce display quality.

-

Adhesives may fail under extreme temperature or humidity.

3. Difficult Repairability

-

Layers are permanently bonded, making repairs challenging.

-

A damaged touch panel often requires replacing the entire module.

4. Limited Design Flexibility

-

Post-lamination modifications are nearly impossible.

-

Adding layers requires a full redesign of the lamination process.

5. Potential Optical Distortions

-

Uneven adhesive application can cause brightness or color inconsistencies.

-

Poor alignment may lead to touch misregistration.

Conclusion

The lamination method for TFT LCDs with capacitive touch screens delivers exceptional optical clarity, touch accuracy, and durability—making it the preferred choice for high-end displays.

However, it comes with higher costs, repair challenges, and manufacturing complexity.

Choosing between OCA vs. OCR and vacuum vs. roll lamination should be based on the target application’s needs. With ongoing material and process innovations, future laminated displays are expected to become more reliable, cost-efficient, and visually superior.