OCA vs. OCR: Choosing the Optimal Lamination Solution for Your Touchscreen

Why Lamination Technology Matters

In devices such as smartphones, tablets, automotive displays, and industrial control panels, a high-quality touchscreen depends on more than just accurate touch response — it also requires crystal-clear visual performance and long-term durability.

At the heart of this lies lamination technology — specifically, the adhesive layer that bonds the touch sensor to the cover glass. Choosing the wrong lamination method can result in poor transparency, touch inaccuracy, delamination, or even moisture and dust intrusion.

Today, we’ll compare two leading lamination solutions: OCA (Optically Clear Adhesive) and OCR (Optically Clear Resin) — explaining how they work and which is best for your touch display project.

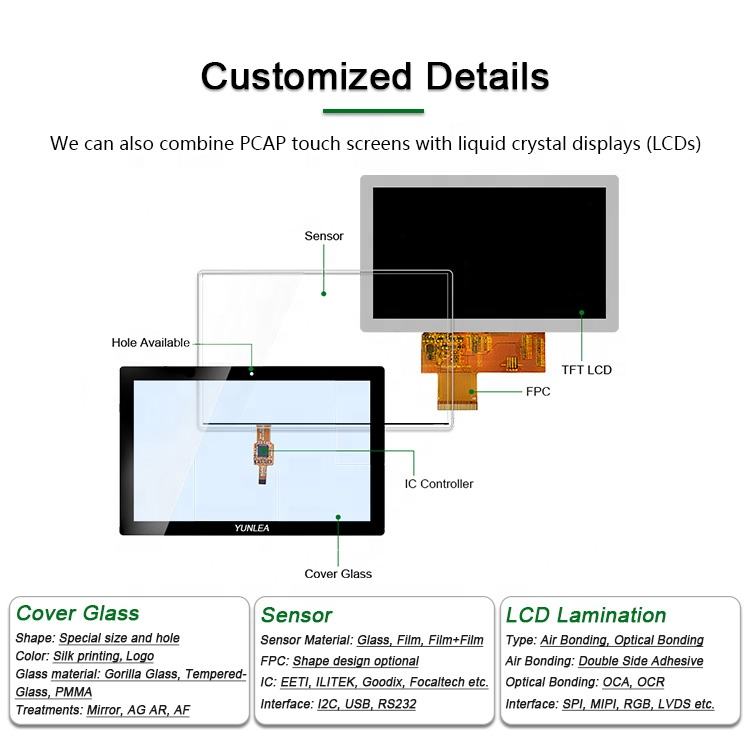

OCA (Optically Clear Adhesive)

OCA is a solid optical adhesive film, often used in capacitive touch panels and display bonding. It is applied via vacuum lamination equipment that ensures precise alignment, uniform pressure, and bubble removal.

Advantages

-

Superior Optical Clarity:

Over 99% light transmittance and very low haze, creating a seamless bonding effect and vivid display. -

Stable and Mature Process:

Excellent thickness uniformity and consistent production yield. -

Clean Process:

No liquid flow—keeps edges and equipment uncontaminated.

Disadvantages

-

Higher Cost:

Both the OCA material and lamination equipment are more expensive. -

Limited Adaptability:

Difficult to apply on curved or irregular surfaces; may produce bubbles on large-size screens. -

Hard to Rework:

Once bonded, it’s almost impossible to remove or repair without damage.

OCR (Optically Clear Resin)

OCR is a liquid adhesive applied by dispensing or coating, then cured by UV or heat to form a transparent bonding layer.

Advantages

-

Excellent Adaptability:

Ideal for curved (2.5D/3D) or flexible OLED screens and irregular shapes. -

Cost-Effective for Large Screens:

Lower material and equipment costs for applications like automotive and digital signage. -

Good Gap Filling:

The liquid resin can fill uneven surfaces, reducing internal stress. -

Repairable:

Can sometimes be reworked using heat and special tools.

Disadvantages

-

Complex Process:

Requires precise control of coating, curing conditions, and UV exposure. -

Flow and Contamination Risks:

May overflow or contaminate IC areas if not sealed properly. -

Optical Stability:

More prone to bubbles, impurities, or yellowing compared to OCA.

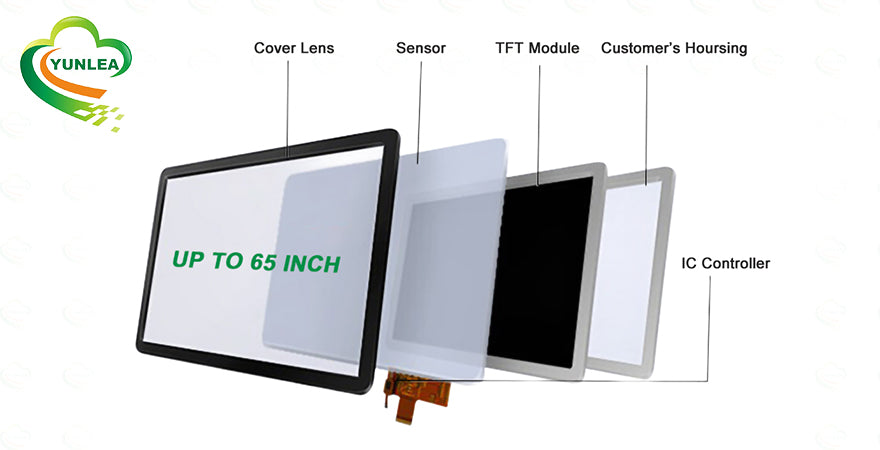

Full Lamination vs. Air Gap: The Structural Difference

1. Air Gap (Frame Lamination)

The Air Gap method bonds only the edges of the touch panel using double-sided tape, leaving an air layer between the sensor and the cover glass.

Impact on Display:

-

The air layer causes light reflection and refraction, making the display appear grayish and less vibrant.

-

Under strong light, a visible “floating effect” occurs, reducing image contrast and quality.

Impact on Touch:

-

Lower signal-to-noise ratio (SNR) due to the increased distance between finger and sensor.

-

Possible interference patterns (Newton’s Rings) and “water ripple” effects under impact.

2. Full Lamination (Using OCA or OCR)

Full Lamination eliminates the air gap by completely filling the space between layers with OCA or OCR adhesive.

Impact on Display:

-

By matching the refractive index of glass, reflection is minimized and contrast is greatly enhanced.

-

Colors become more vivid, brightness improves, and sunlight readability is significantly better — the hallmark of premium devices.

Impact on Touch:

-

Higher touch sensitivity and accuracy thanks to improved capacitance change (ΔC).

-

Greater mechanical strength, better resistance to deformation, and improved dust and moisture sealing.

Choosing the Right Solution

Every project has unique requirements.

If your design involves flat surfaces, high optical standards, and stable mass production, choose OCA.

If you need to laminate curved, flexible, or large-format screens, OCR may be your best choice.

Yunlea provides customized lamination solutions for both OCA and OCR bonding, ensuring the best balance between optical clarity, touch performance, and reliability.

If you’re unsure which technology suits your application, contact info@yunlea.com — our engineering team will help you choose the optimal path for your touchscreen design.