Notizie

Discover Yunlea's systematic five-step approach to developing custom capacitive touchscreens, from conceptualization to mass production. Each stage is meticulously designed to ensure that the final product meets the highest technical and practical standards.

- Definition: Understand the client’s needs through a detailed questionnaire, aligning project objectives and setting a clear foundation.

- Concept: Develop prototypes based on initial specifications, allowing early adjustments and proof of concept.

- Design: Finalize all aspects of the touchscreen, from electrical design to physical dimensions, with detailed engineering efforts.

- Validation: Clients validate the custom-designed touchscreen to ensure it meets all requirements and performs as expected.

- Production: Begin with a short production run to finalize processes, scaling up to full mass production after quality checks.

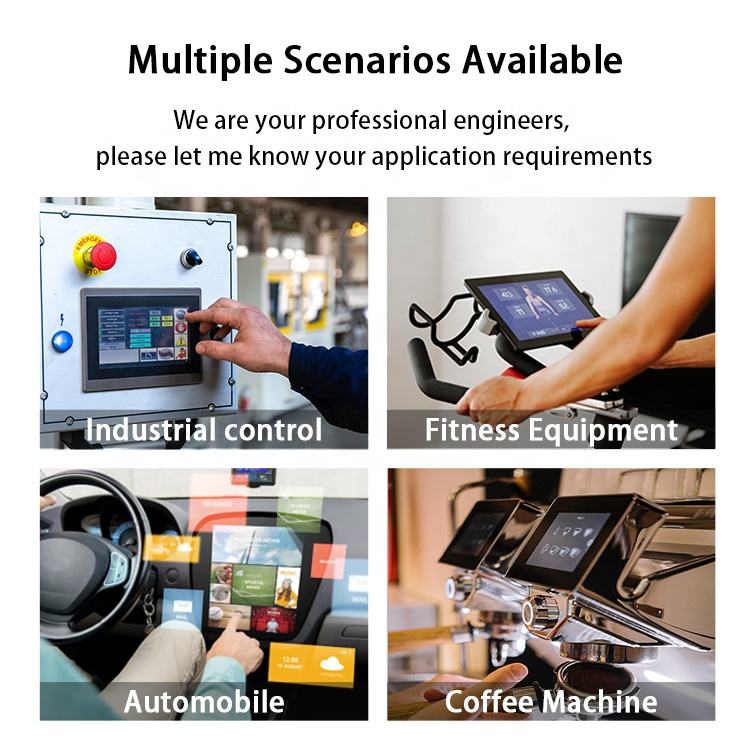

This process ensures that Yunlea delivers top-quality, tailored touchscreen solutions for various applications. Contact Yunlea today to customize your capacitive touch screen!

Touch screen manufacturing is a complex process that involves numerous steps to ensure the final product is both functional and durable. At Yunlea, we recognize and address the various challenges that can arise during production to deliver high-quality touch screens that meet industry standards. Here’s an in-depth look at the common issues encountered in touch screen manufacturing and how we tackle them.

Continue reading