Top Challenges in Touch Screen Manufacturing: Insights from Yunlea

Producing touch screens involves complex manufacturing processes, and several problems may occur during production:

Material Defects:

Imperfections in raw materials, such as glass or conductive layers, can result in dead zones, non-responsive areas, or overall fragility in the touch screens. At Yunlea, we source high-quality materials and conduct thorough inspections to minimize defects.

Calibration Accuracy:

Ensuring that the touch screen accurately registers touch at the correct locations requires precise calibration. Miscalibration can lead to touch points that do not align with the displayed content. We employ advanced calibration techniques to maintain high accuracy.

Sensitivity Uniformity:

Achieving uniform sensitivity across the entire screen can be challenging. Inconsistencies can result in certain areas being too sensitive or not responsive enough. Our rigorous testing processes help ensure uniform sensitivity and optimal performance.

Environmental Durability:

Touch screens need to be durable enough to withstand the conditions they will be exposed to, including temperature extremes, humidity, and UV exposure. Failing to account for this can lead to screens that malfunction or degrade over time. Yunlea designs touch screens with enhanced durability to withstand harsh environments.

Electromagnetic Interference:

The touch screen must be designed to cope with electromagnetic interference that can originate from other components of the device or external sources, which could affect its performance. Our designs incorporate shielding and advanced circuitry to mitigate interference.

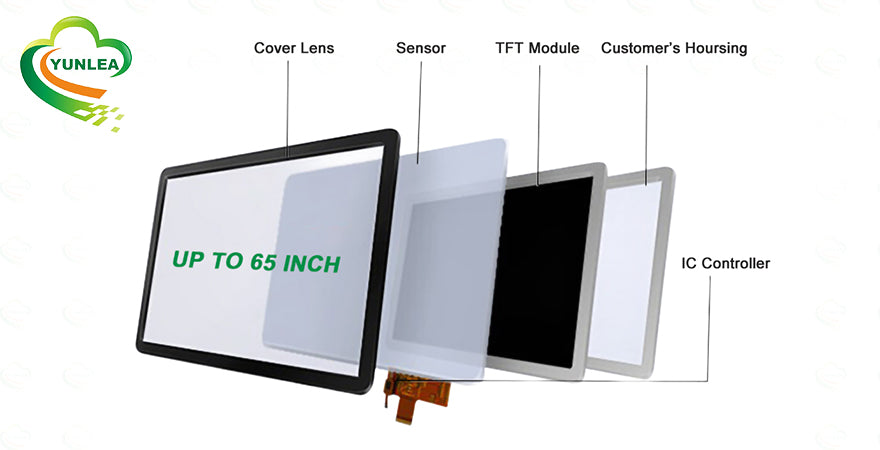

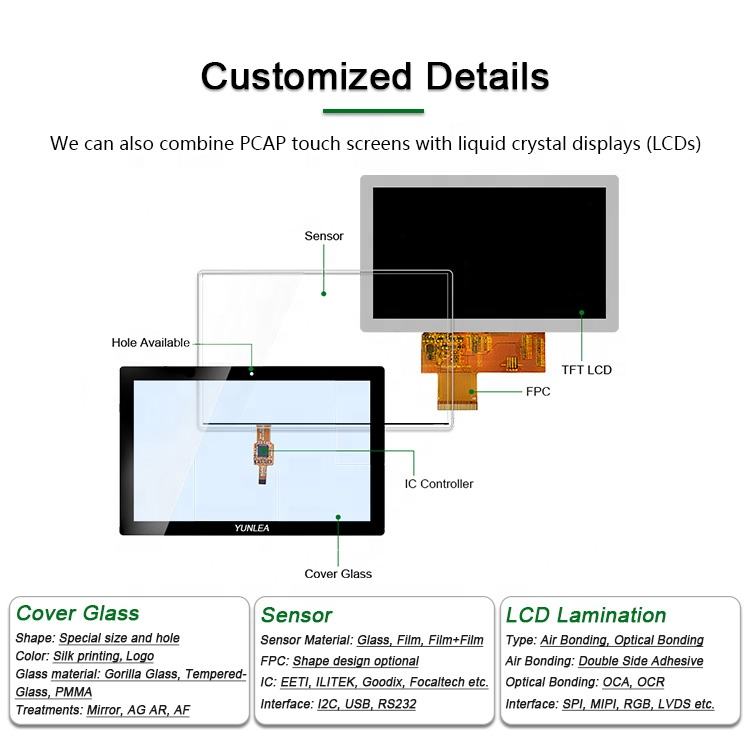

Integration with Other Components:

The touch screen must be compatible with other components of the device, such as the TFT LCD or OLED display it is bonded with. LCD with touch screen can be air bonding or optical bonding. Issues here can lead to a loss of functionality or clarity. Yunlea uses precise bonding techniques to ensure seamless integration.

Cost Overruns:

The production of touch screens can be cost-intensive, and there is a risk of cost overruns due to the high-quality materials and precision required for manufacturing. We optimize our production processes to manage costs effectively.

Quality Control Failures:

Inadequate quality control can allow defective products to reach the market, leading to high return rates and damage to the manufacturer's reputation. At Yunlea, we implement stringent quality control measures to maintain product excellence.

Supply Chain Issues:

Delays in the supply chain for sourcing materials or disruptions due to geopolitical issues can halt or slow down production, leading to an inability to meet market demand. We maintain a robust supply chain and contingency plans to ensure uninterrupted production.

Technological Advances:

The rapid pace of technology means that touch screen manufacturers must constantly innovate to keep up with new standards and features, which can be both a production challenge and a financial strain. Using high-performance controller chips like EETI, ILITEK, GOODIX, and FOCALTECH, we stay ahead of technological trends.

Labor Skill Requirements:

Producing high-quality touch screens requires skilled labor and expertise. Shortages of skilled workers or inadequate training can result in production errors and reduced manufacturing efficiency. Yunlea invests in training and retaining skilled professionals to ensure high-quality manufacturing.

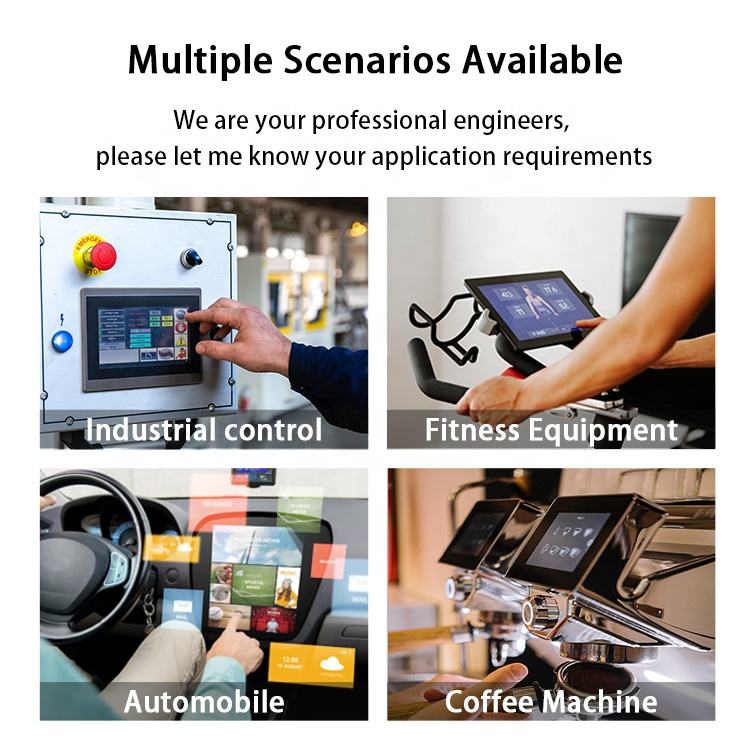

Manufacturers address these challenges through rigorous testing, quality control measures, research and development, and by staying abreast of technological advancements to ensure that the capacitive touch screens they produce meet the desired standards of quality and durability.

At Yunlea, our commitment to quality and innovation drives us to overcome these challenges and deliver superior touch screen solutions for various applications. If you have any complex product applications that require high-quality touch screens, please feel free to contact us.

#Yunlea #TouchScreen #ManufacturingChallenges #CapacitiveTouchScreen #IndustrialTouchScreen #QualityControl #TechnologicalInnovation #Durability #Reliability

Material Defects:

Imperfections in raw materials, such as glass or conductive layers, can result in dead zones, non-responsive areas, or overall fragility in the touch screens. At Yunlea, we source high-quality materials and conduct thorough inspections to minimize defects.

Calibration Accuracy:

Ensuring that the touch screen accurately registers touch at the correct locations requires precise calibration. Miscalibration can lead to touch points that do not align with the displayed content. We employ advanced calibration techniques to maintain high accuracy.

Sensitivity Uniformity:

Achieving uniform sensitivity across the entire screen can be challenging. Inconsistencies can result in certain areas being too sensitive or not responsive enough. Our rigorous testing processes help ensure uniform sensitivity and optimal performance.

Environmental Durability:

Touch screens need to be durable enough to withstand the conditions they will be exposed to, including temperature extremes, humidity, and UV exposure. Failing to account for this can lead to screens that malfunction or degrade over time. Yunlea designs touch screens with enhanced durability to withstand harsh environments.

Electromagnetic Interference:

The touch screen must be designed to cope with electromagnetic interference that can originate from other components of the device or external sources, which could affect its performance. Our designs incorporate shielding and advanced circuitry to mitigate interference.

Integration with Other Components:

The touch screen must be compatible with other components of the device, such as the TFT LCD or OLED display it is bonded with. LCD with touch screen can be air bonding or optical bonding. Issues here can lead to a loss of functionality or clarity. Yunlea uses precise bonding techniques to ensure seamless integration.

Cost Overruns:

The production of touch screens can be cost-intensive, and there is a risk of cost overruns due to the high-quality materials and precision required for manufacturing. We optimize our production processes to manage costs effectively.

Quality Control Failures:

Inadequate quality control can allow defective products to reach the market, leading to high return rates and damage to the manufacturer's reputation. At Yunlea, we implement stringent quality control measures to maintain product excellence.

Supply Chain Issues:

Delays in the supply chain for sourcing materials or disruptions due to geopolitical issues can halt or slow down production, leading to an inability to meet market demand. We maintain a robust supply chain and contingency plans to ensure uninterrupted production.

Technological Advances:

The rapid pace of technology means that touch screen manufacturers must constantly innovate to keep up with new standards and features, which can be both a production challenge and a financial strain. Using high-performance controller chips like EETI, ILITEK, GOODIX, and FOCALTECH, we stay ahead of technological trends.

Labor Skill Requirements:

Producing high-quality touch screens requires skilled labor and expertise. Shortages of skilled workers or inadequate training can result in production errors and reduced manufacturing efficiency. Yunlea invests in training and retaining skilled professionals to ensure high-quality manufacturing.

Manufacturers address these challenges through rigorous testing, quality control measures, research and development, and by staying abreast of technological advancements to ensure that the capacitive touch screens they produce meet the desired standards of quality and durability.

At Yunlea, our commitment to quality and innovation drives us to overcome these challenges and deliver superior touch screen solutions for various applications. If you have any complex product applications that require high-quality touch screens, please feel free to contact us.

#Yunlea #TouchScreen #ManufacturingChallenges #CapacitiveTouchScreen #IndustrialTouchScreen #QualityControl #TechnologicalInnovation #Durability #Reliability