Touchscreen Drop Testing: How It Works and What Passes

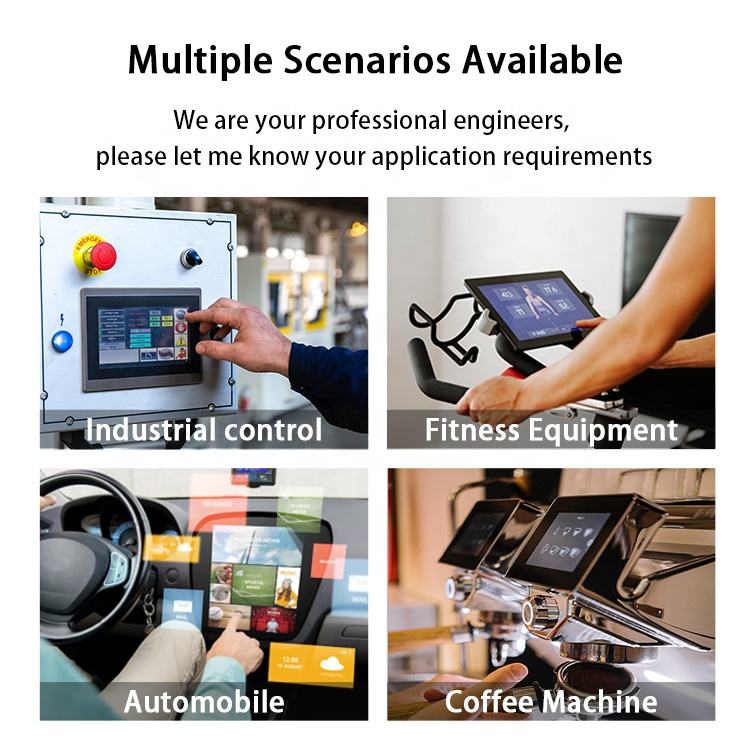

As a professional touchscreen manufacturer, Yunlea takes product reliability seriously — and drop testing is one of the most important steps in ensuring that every screen we produce can survive real-world accidents.

How Drop Testing Works

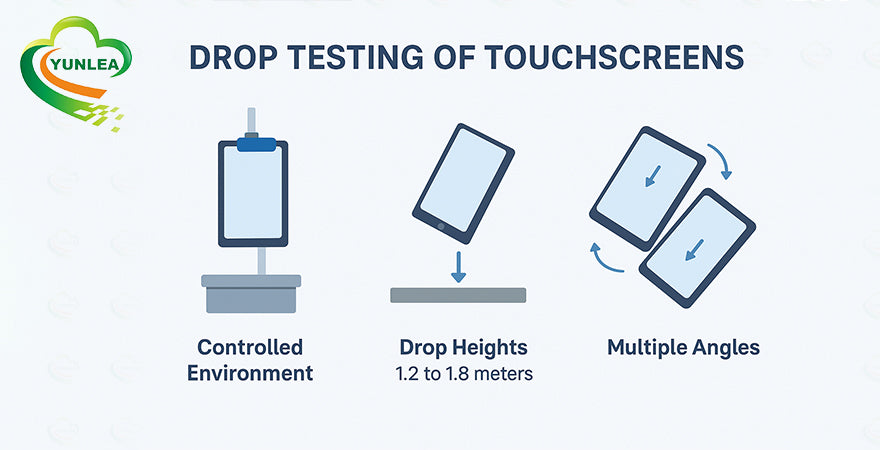

1. Controlled Environment:

All tests are conducted in specialized labs. Devices are placed in secure fixtures and dropped onto hard surfaces such as stone or steel, replicating real-world floors.

2. Drop Heights:

Typical drop heights range from 1.2 to 1.8 meters, similar to falling from a user’s hand or pocket. Industry standards such as ISTA-3A guide the testing process.

3. Multiple Angles:

Each device is dropped on all sides — front, back, left, right, top, bottom, and especially its corners. Every orientation is tested multiple times to ensure consistent durability.

Passing Criteria for Touchscreens

A touchscreen must meet strict quality requirements to pass:

-

No major cracks, shattering, peeling, or deformation of the frame.

-

Touch performance remains flawless — no missed touches, ghost touches, or dead zones.

-

Display integrity remains perfect — no discoloration, light leakage, or bright spots.

-

Internal structure remains secure — verified via X-ray or disassembly to ensure components are not damaged or loose.

Why Strict Testing Matters

-

Improved Product Design: Identifying weak points allows engineers to enhance frames, bumpers, and protective layers.

-

User Safety & Satisfaction: Stronger screens reduce breakage, improving customer trust and experience.

-

Cost Efficiency: Fewer repairs and returns save costs for both manufacturer and clients.

At Yunlea, we see drop testing as a final exam for our touchscreens. Only products that remain fully functional and structurally sound under rigorous conditions earn the Yunlea seal of quality.